Revolutionizing Clean Energy Generation

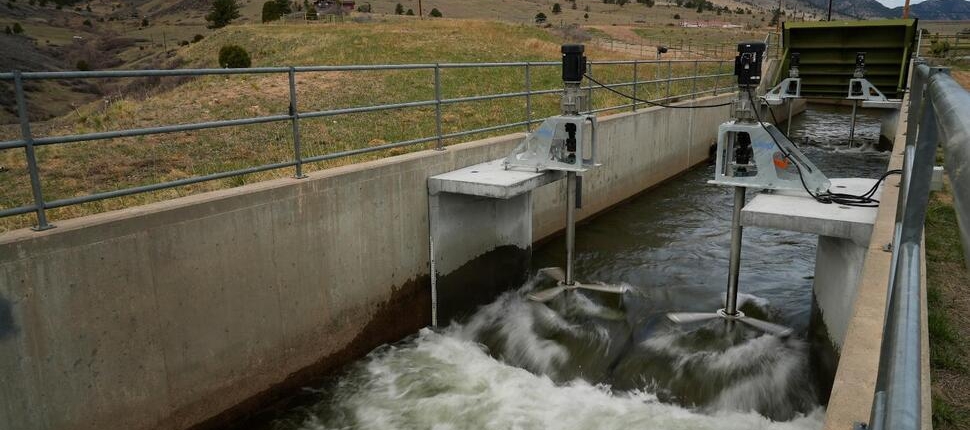

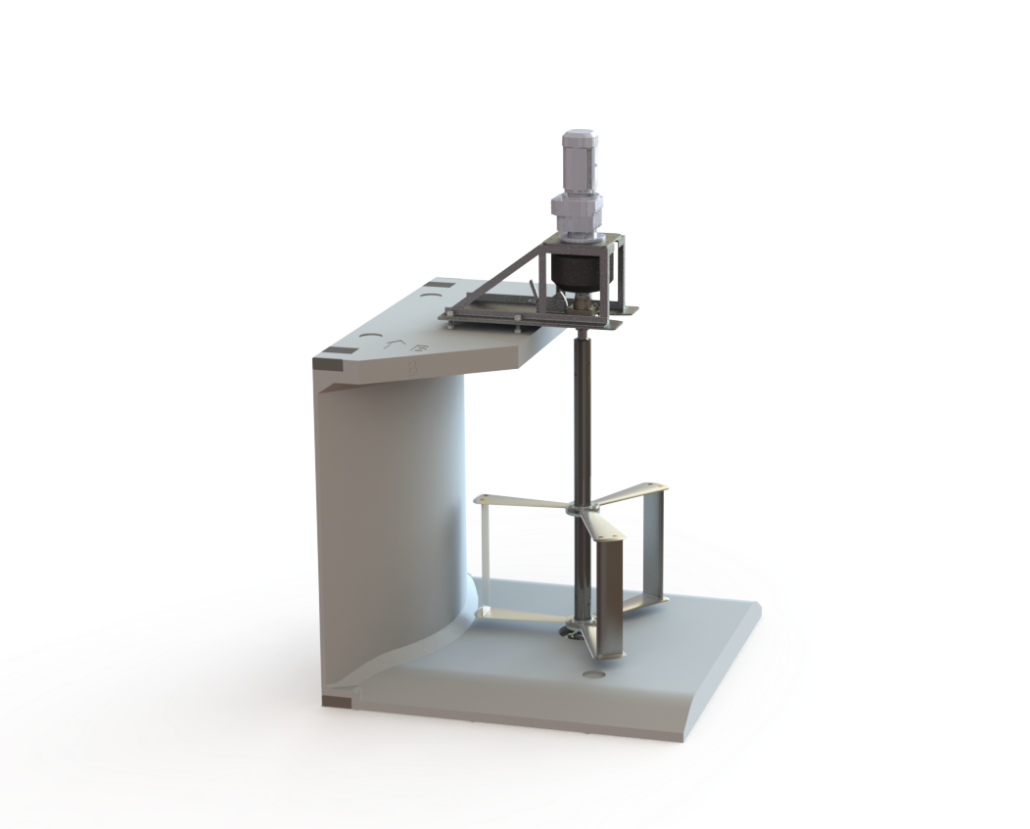

Discover how Emrgy’s hydrokinetic technology transforms clean energy production without traditional dams. Generating 5 to 25 kilowatts per turbine, this innovative approach harnesses flowing water’s energy, delivering reliable, cost-effective power while repurposing water channels for clean energy.